AI for Field Service in Australia: 12 High-ROI Use Cases

Discover 12 practical AI use cases for Australian field service businesses. From diagnostic automation to predictive maintenance, learn which applications deliver the fastest returns.

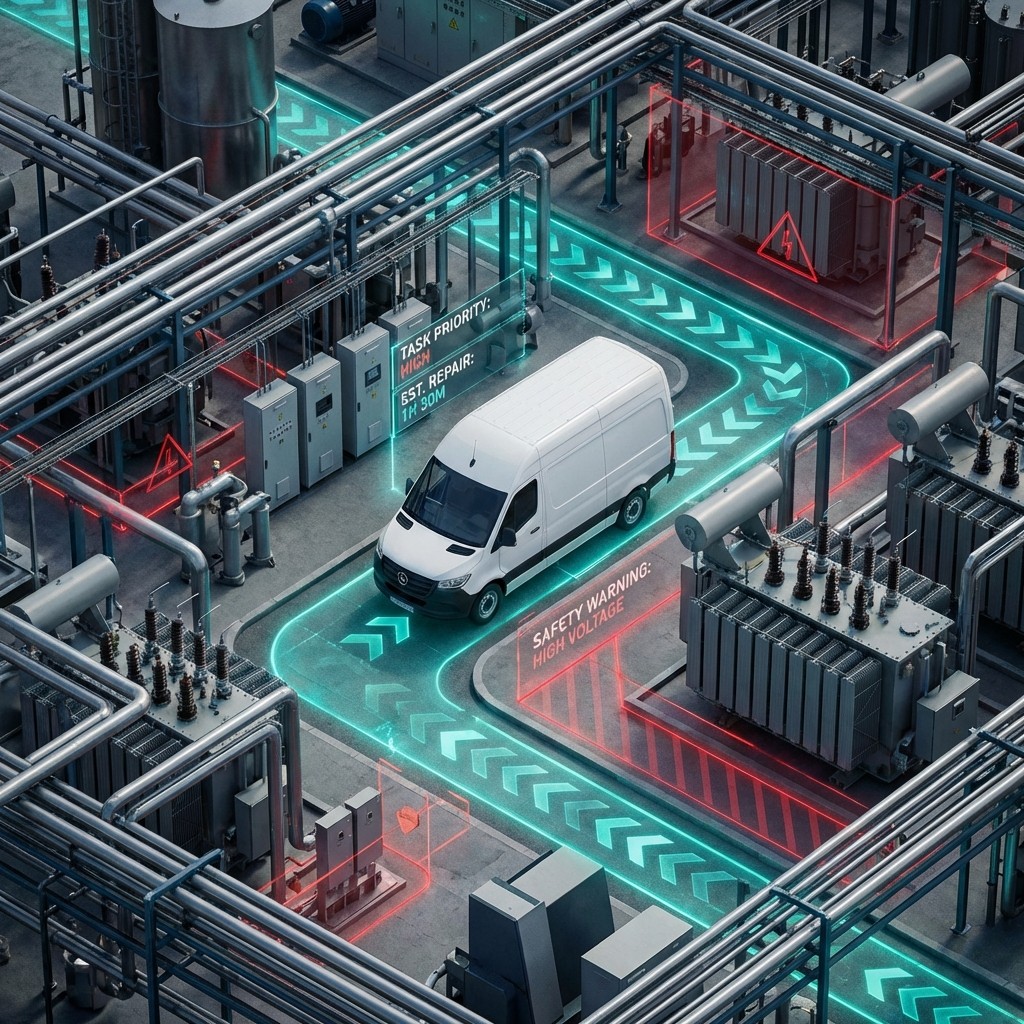

The Field Service AI Opportunity

A Melbourne HVAC technician arrives at a commercial site. Compressor down, temperature rising, client anxious. She captures thermal images, records audio patterns, and uploads diagnostic codes. Within seconds, AI analysis flags a compressor valve failure with high confidence. She has the right parts, completes the fix, and moves to her next job, significantly faster than traditional troubleshooting.

This scenario is increasingly common across Australian field service operations. AI systems that deliver measurable returns are moving from enterprise-only technology to accessible solutions for mid-market businesses.

The challenge for most organisations isn't whether AI can help, it's identifying which use cases deliver genuine ROI without requiring enterprise-scale implementation resources. Mid-market field service businesses typically lack dedicated IT teams for complex deployments, yet need more than basic automation tools.

This guide examines 12 AI use cases specifically relevant to Australian field service operations, with practical guidance on where each delivers the strongest returns.

What Is AI for Field Service?

AI for field service automates diagnostics, dispatch coordination, and knowledge access for technicians. These systems integrate multiple data types text, images, voice recordings, and sensor data—to support decisions in the field.

Core capabilities include:

Anomaly detection that analyses current conditions against known failure patterns

Multimodal processing that combines thermal imaging, audio analysis, and diagnostic codes

Automated resolution for routine issues with human oversight for critical decisions

Knowledge retrieval that gives technicians instant access to technical documentation

The technology doesn't replace technicians—it amplifies their efficiency by reducing diagnostic guesswork and administrative friction.

The Australian mid-market context: Enterprise platforms often require significant implementation resources and extended timelines. Meanwhile, basic automation tools lack the diagnostic sophistication to meaningfully transform operations. Australian organisations also face specific data residency considerations that influence platform selection.

12 High-ROI AI Use Cases for Field Service

1. Multimodal Diagnostic AI

What it does: Integrates thermal imaging, audio analysis, diagnostic codes, and service history into unified failure identification.

How it works: The system processes multiple data types simultaneously to build comprehensive equipment assessments. In HVAC applications, this means analysing thermal patterns, compressor sounds, error codes, and maintenance records together rather than in isolation.

ROI drivers:

Reduced diagnostic time per incident (often 30-60 minutes saved)

Higher first-time fix rates through more accurate diagnosis

Fewer return visits from misdiagnosis

Best for: HVAC, refrigeration, and equipment-intensive operations requiring rapid failure diagnosis.

Implementation considerations:

Requires thermal imaging cameras and audio capture devices

Historical data quality directly impacts effectiveness

Works best with established service documentation

2. Intelligent Dispatch Optimisation

What it does: Automates technician assignment based on skills, location, availability, and job requirements.

How it works: AI analyses job characteristics, matches them against technician skill profiles, and optimises routing to minimise travel time while maximising first-time fix probability.

ROI drivers:

Improved first-time fix rates through better skill matching

Reduced travel time and fuel costs

Increased daily service capacity per technician

Best for: Multi-technician operations with varied job types and geographic spread.

Implementation considerations:

Requires accurate technician skill profiles

Integration with existing scheduling platforms

Ongoing maintenance of certification and capability records

3. Knowledge Retrieval AI Agents

What it does: Provides instant access to technical documentation through conversational queries.

How it works: AI indexes technical manuals, service bulletins, and internal troubleshooting guides into a searchable knowledge base. Technicians ask questions naturally and receive contextually relevant procedures.

ROI drivers:

Eliminated time searching through manuals (often 10-15 minutes per incident)

Faster onboarding for new technicians

Consistent application of best practices across the team

Best for: Organisations with extensive technical documentation where field teams need rapid access to procedures.

Implementation considerations:

Documentation quality directly affects retrieval accuracy

Requires comprehensive indexing of all relevant materials

Works best with structured, well-organised technical content

Not sure which AI use case fits your operation?

Our AI Discovery Workshop helps field service businesses identify the highest-impact opportunities. We map your current processes, understand your specific challenges, and design solutions that integrate with your existing systems.

Investment: $2,000-$5,000 with full money-back guarantee

4. Predictive Maintenance Scheduling

What it does: Analyses equipment sensor data to forecast failure likelihood and schedule preventive service before breakdowns occur.

How it works: IoT sensors monitor equipment performance patterns. AI identifies anomalies indicating impending failures and automatically schedules maintenance appointments before critical breakdowns.

ROI drivers:

Shift from reactive emergency service to planned maintenance

Reduced emergency callout costs

Extended equipment lifespan through timely intervention

Improved customer satisfaction from reduced downtime

Best for: Organisations managing equipment with IoT sensor capabilities and service contracts with preventive maintenance commitments.

Implementation considerations:

Requires IoT sensor integration with monitored equipment

Prediction accuracy improves as historical failure data accumulates

Initial setup period before predictions become reliable

5. Automated First-Call Resolution

What it does: Diagnoses issues remotely and guides customers through troubleshooting before dispatching technicians.

How it works: AI-powered systems walk customers through diagnostic steps, identifying issues that can be resolved without a site visit. Complex issues still trigger dispatch, but with better context for faster resolution.

ROI drivers:

Eliminated unnecessary site visits for simple issues

Reduced call handling time

Lower cost per incident for resolvable problems

Better technician utilisation on complex work

Best for: Organisations with high call volumes and common issues that customers can resolve with guidance.

Implementation considerations:

Customer acceptance varies—some prefer immediate human contact

Limited to genuinely simple problems

Requires well-designed troubleshooting flows

6. Parts and Inventory Optimisation

What it does: Predicts parts requirements based on job history and equipment data, optimising van stock levels.

How it works: AI analyses historical parts usage patterns and upcoming job types to recommend optimal van inventory. Automated reordering ensures critical parts remain available without excessive stock accumulation.

ROI drivers:

Reduced return visits from missing parts

Lower inventory carrying costs

Improved first-time fix rates

Better cash flow through optimised stock levels

Best for: Organisations with extensive parts inventory across mobile technicians.

Implementation considerations:

Requires integration with parts management systems

Historical usage data quality affects prediction accuracy

Works best with consistent parts coding and tracking

7. Quality Assurance and Compliance Monitoring

What it does: Automatically reviews service documentation and flags missing information or compliance gaps before job closure.

How it works: Rule-based validation checks service reports against compliance checklists in real-time. Issues are flagged immediately, allowing technicians to complete documentation before leaving site.

ROI drivers:

Reduced compliance-related rework

Complete audit trails for regulatory requirements

Fewer failed audits and associated penalties

Consistent documentation quality across the team

Best for: Regulated industries with strict documentation requirements (utilities, healthcare facilities, food service).

Implementation considerations:

Requires clear compliance rules translated into validation logic

Human oversight still needed for critical decisions

Initial setup to configure validation rules

8. Customer Communication Automation

What it does: Automates appointment confirmations, arrival notifications, and follow-up communications.

How it works: Integration with scheduling platforms triggers automated messages at key service milestones. Customers receive timely updates without staff intervention.

ROI drivers:

Eliminated manual coordination calls

Reduced inbound service enquiries

Improved customer satisfaction scores

Freed administrative staff for higher-value work

Best for: High-volume service operations requiring consistent customer updates.

Implementation considerations:

Requires integration with scheduling and communication platforms

Some customers prefer human contact for complex issues

Message templates need careful design

Looking to automate customer communications?

We help field service businesses implement AI solutions that integrate with existing systems. Our discovery-first approach ensures we understand your specific workflow before recommending solutions.

9. Workforce Skills Gap Analysis

What it does: Analyses service outcomes against technician skill profiles to identify training needs.

How it works: AI examines patterns in service outcomes—first-time fix rates, return visits, job duration—correlated with technician assignments. This reveals specific skill deficiencies affecting performance.

ROI drivers:

Data-driven training prioritisation

Improved first-time fix rates through targeted development

Better training budget allocation

Measurable skill improvement tracking

Best for: Growing organisations with multi-level technician teams.

Implementation considerations:

Requires comprehensive service outcome data

Training implementation remains a manual process

Works best with established performance tracking

10. Anomaly Detection with Pattern Recognition

What it does: Analyses current service context against a knowledge base of historical incidents to identify probable root causes.

How it works: The system cross-references current symptoms with documented failure modes, then matches probable causes to established recovery protocols.

ROI drivers:

Faster root cause identification

Consistent diagnostic approach across technicians

Pattern recognition across fleet/customer base

Reduced escalation to senior technicians

Best for: Organisations with extensive service history data and recurring issue patterns.

Implementation considerations:

Requires well-documented service history

Initial setup demands failure mode documentation

Pattern recognition improves as data accumulates

11. Remote Diagnostics and Triage

What it does: Enables preliminary diagnosis before technician dispatch through remote data collection and analysis.

How it works: Customers or on-site staff capture diagnostic information (photos, error codes, sensor readings) that AI analyses to determine likely issues and required expertise before dispatch.

ROI drivers:

Better technician-job matching through pre-diagnosis

Reduced diagnostic time on site

Appropriate parts loaded before arrival

Faster resolution for customers

Best for: Organisations serving equipment with remote monitoring capabilities or tech-savvy customer bases.

Implementation considerations:

Depends on customer willingness to capture diagnostic data

Requires reliable data transmission infrastructure

Works best with standardised diagnostic protocols

12. Data Residency-Compliant AI Implementation

What it does: Deploys AI capabilities while ensuring all data processing occurs within Australian data centres.

How it works: Architecture designed to keep customer data, AI processing, and model training within Australian jurisdiction, satisfying regulatory requirements for sensitive industries.

ROI drivers:

Compliance with Australian Privacy Principles

Meets sector-specific data residency requirements

Reduced compliance risk and audit burden

Customer confidence in data handling

Best for: Organisations in regulated industries (healthcare, utilities, government services) with strict data sovereignty requirements.

Implementation considerations:

May limit platform options

Requires verification of entire processing chain

Ongoing compliance monitoring needed

Use Case Comparison

Use Case | Implementation Complexity | Typical ROI Timeline | Best For |

|---|---|---|---|

Multimodal Diagnostics | High | 3-6 months | Equipment-intensive operations |

Dispatch Optimisation | Medium | 1-3 months | Multi-technician fleets |

Knowledge Retrieval | Medium | 1-2 months | Documentation-heavy environments |

Predictive Maintenance | High | 6-12 months | IoT-enabled equipment |

First-Call Resolution | Medium | 2-4 months | High call volume operations |

Parts Optimisation | Medium | 3-6 months | Mobile technician fleets |

Compliance Monitoring | Low-Medium | 1-2 months | Regulated industries |

Customer Communication | Low | 1 month | High-volume operations |

Skills Gap Analysis | Medium | 3-6 months | Growing teams |

Anomaly Detection | Medium-High | 3-6 months | Data-rich organisations |

Remote Diagnostics | Medium | 2-4 months | Tech-enabled equipment |

Data Residency Compliance | High | Varies | Regulated industries |

Choosing the Right Use Cases

Start with Pain Points, Not Technology

The most successful AI implementations address specific operational friction rather than deploying technology for its own sake. Ask:

Where do technicians spend the most time on non-productive activities?

What causes return visits and callbacks?

Where does information get lost or delayed?

What compliance requirements create administrative burden?

Consider Implementation Complexity

Mid-market organisations typically lack dedicated AI teams. Prioritise use cases that:

Integrate with existing systems rather than requiring replacement

Deliver measurable value within 90 days

Can be implemented incrementally

Don't require extensive custom development

Match to Your Data Maturity

AI effectiveness depends heavily on data quality:

Limited historical data: Start with knowledge retrieval or communication automation

Good service records: Anomaly detection and skills analysis become viable

IoT sensor infrastructure: Predictive maintenance delivers strong returns

Well-documented processes: Compliance monitoring provides immediate value

Factor in Change Management

The best technology fails without user adoption. Consider:

Technician comfort with new tools and processes

Training requirements and timeline

Integration with existing workflows

Stakeholder buy-in for process changes

Implementation Approach

Phase 1: Discovery and Assessment

Before selecting technology, understand your current state:

Map existing workflows and pain points

Assess data quality and availability

Identify quick wins versus strategic investments

Evaluate integration requirements with existing systems

Phase 2: Pilot Implementation

Start contained:

Select one use case with clear success metrics

Implement with a subset of technicians or job types

Measure results against baseline

Gather user feedback and refine

Phase 3: Scale and Expand

Build on proven success:

Document what worked and what didn't

Expand successful pilots across the organisation

Add complementary use cases that leverage existing infrastructure

Establish ongoing monitoring and improvement processes

Ready to identify the right AI use cases for your operation?

We help Australian field service businesses implement AI solutions that deliver measurable returns. Our AI Discovery Workshop maps your current processes, identifies the highest-impact opportunities, and designs solutions that work with your existing systems.

Our approach focuses on contained, defensible use cases with clear ROI targets—not open-ended AI experimentation.

Investment: $2,000-$5,000 with full money-back guarantee

Frequently Asked Questions

What is AI for field service management?

AI for field service automates diagnostics, dispatch coordination, and knowledge access for technicians. These systems integrate multiple data types—thermal imaging, audio patterns, diagnostic codes, service history—to support field decisions and reduce time spent on non-productive activities.

Which AI use case should I start with?

Start with your biggest operational pain point. If technicians spend significant time searching for information, knowledge retrieval delivers quick wins. If scheduling is chaotic, dispatch optimisation helps. If compliance documentation is problematic, automated validation reduces rework. Match the use case to your specific friction.

How long before I see ROI from field service AI?

Timeline varies by use case. Communication automation can show returns within weeks. Knowledge retrieval and dispatch optimisation typically deliver within 1-3 months. Predictive maintenance requires longer data accumulation—expect 6-12 months for reliable predictions.

Do I need IoT sensors for field service AI?

Not for all use cases. Knowledge retrieval, dispatch optimisation, and compliance monitoring work without sensor infrastructure. Predictive maintenance and some diagnostic applications require sensor data. Start with use cases that leverage your existing data before investing in new infrastructure.

How does AI field service affect my technicians?

Well-implemented AI amplifies technician effectiveness rather than replacing expertise. It handles information retrieval and administrative tasks, freeing technicians for skilled work. The key is positioning AI as a tool that makes their jobs easier, not a system that monitors or replaces them.

What data residency requirements apply in Australia?

Australian Privacy Principles govern personal information handling. Specific industries (healthcare, utilities, government) may have additional requirements. If you're handling sensitive customer data, verify that AI processing occurs within Australian data centres and understand your compliance obligations.

What's the difference between enterprise and mid-market AI solutions?

Enterprise platforms typically offer comprehensive capabilities but require significant implementation resources and extended timelines. Mid-market solutions prioritise rapid deployment and contained use cases over feature breadth. The right choice depends on your internal resources and how quickly you need to see results.

Summary

AI for field service delivers genuine value when implementations address specific operational friction rather than deploying technology for its own sake. The 12 use cases outlined here represent proven applications with documented returns across Australian field service operations.

Key principles for success:

Start with pain points - Let operational challenges guide technology selection

Match complexity to resources - Don't attempt enterprise-scale implementations without enterprise resources

Consider data maturity - AI effectiveness depends on data quality

Plan for adoption - Technology without user buy-in fails regardless of capability

Measure and iterate - Establish clear success metrics and refine based on results

The organisations seeing the best returns treat AI as an operational improvement tool rather than a technology project. They start small, prove value, and expand based on demonstrated results.

AI2Easy helps Australian field service businesses implement AI solutions that integrate with existing systems and deliver measurable operational improvements. Our discovery-first approach ensures we understand your specific challenges before recommending solutions.